Temperature sensors are widely used in industry for measurement and controlling the process and production quality checks. Depending on the temperature range and required precision either thermocouples or RTD sensors are selected. Thermocouples are available in variety of configuration like J, K, R, S, T, N, E type etc and is formed with 2 elements / legs made up of two dissimilar materials. Classification J, K, T, E, N is termed as Base Metal thermocouple and are used in lower and moderate high temperatures whereas R, S type are termed as Noble Metal thermocouples. Noble metal sensors are used for high temperature measurements.

RTD work on a basic relation between metals and temperature. Resistance of metal to the electricity flow increases with rise in temperature. Similarly, as the temperature of the RTD resistance element increases, the electrical resistance, measured in ohms (Ω), increases. RTD elements are commonly specified according to their resistance in ohms at zero degrees Celsius. The most common RTD specification is 100 Ω, which means that at 0°C the RTD element should demonstrate 100 Ω resistances. RTD sensors are formed in 2, 3 and 4 wire configuration. 4 wire configurations is precise and accurate over 3 wires.

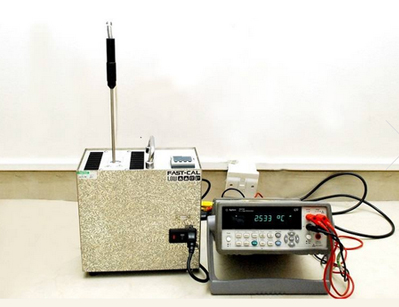

At Calitron we calibrate temperature sensors from (-) 196 °C to 1200°C with reasonably lower measurement uncertainty.